Pumps

Centrifugal Pumps, Booster Pumps

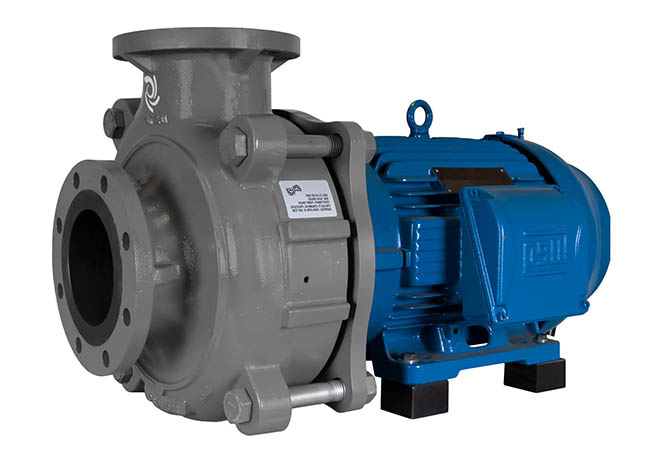

Centrifugal Pumps

Centrifugal Pumps

Centrifugal pumps are hydraulic machines characterised by their ability to transmit energy to fluids (especially liquids) through centrifugal force. The main purpose is to transfer fluids by increasing the pressure. Centrifugal pumps may have different designs, but their operating principle and fluid dynamic characteristics are always the same.

Schematically, centrifugal pumps consist of an impeller or rotor that rotates inside a casing.

The bladed impeller comprises a series of vanes, preferably of radial design, which transmit kinetic energy to the pumped fluid.

The pump casing is equipped with suction and discharge nozzles for the pumped fluid. The suction nozzle has an axis that corresponds to the axis of rotation of the impeller, while the discharge nozzle has an axis perpendicular to the axis of the impeller, but always lying in the same plane as the turbine.

Centrifugal Pumps: Operating Principle

The pumped fluid enters continuously through the pump’s suction nozzle in the centre of the impeller.

From there, it is accelerated in a radial direction to the ends of the impeller, where it is discharged into the casing.

The liquid flow is accelerated by the thrust that the rotor blades, thanks to their curvature, transmit to the flow itself. In this way, the liquid acquires energy, mainly in the form of an increase in its average speed (kinetic energy).

Inside the casing, the liquid is slowed down by the progressively increasing cross-section in the direction of movement.

Such an increase in cross-sectional area is usually achieved by designing the peripheral part of the body (tube aerator) in the form of a spiral with a cross-sectional area (usually circular, trapezoidal or rectangular) that varies from zero up to the cross-sectional area of the discharge.

In this way, the kinetic energy of the fluid is converted into pressure energy.

Boosters pumps

What is a Water Booster Pump?

How does a Booster Pump work?

A booster pump increases the water pressure and, in many cases, improves the flow. A booster pump works in a similar way to a fan. A fan has blades that rotate to increase air movement, and a booster pump has an impeller inside that increases the flow rate and water pressure in the same way.

What are the components of a Booster Pump?

Most water booster pumps, regardless of the manufacturer, contain the same basic components:

- Motor

- Impellers

- Inlet and outlet

- Pressure or flow sensing device

Booster pumps are equipped with an impeller that moves water in and out of the inlet. A motor turns the impellers. Booster pumps differ in the way they draw in water and discharge it. Some booster pumps use a spinning propeller, while others use an oscillating diaphragm. Oscillating diaphragm pumps propel water using two oscillating or rotating plates – one with cuts and one with indentations. When the plates come together, they compress the cups and expel the water. When the plates open, more water is drawn in.

FSS

Smart Control

LET'S GET

Protected from Fire

We take a comprehensive approach to fire safety covering all aspects from the installation of fire alarms and extinguishers to fire risk assessments and emergency lighting. We service all fire safety equipment, fire panels & alarm systems.

Subscribe Now

To our news letter